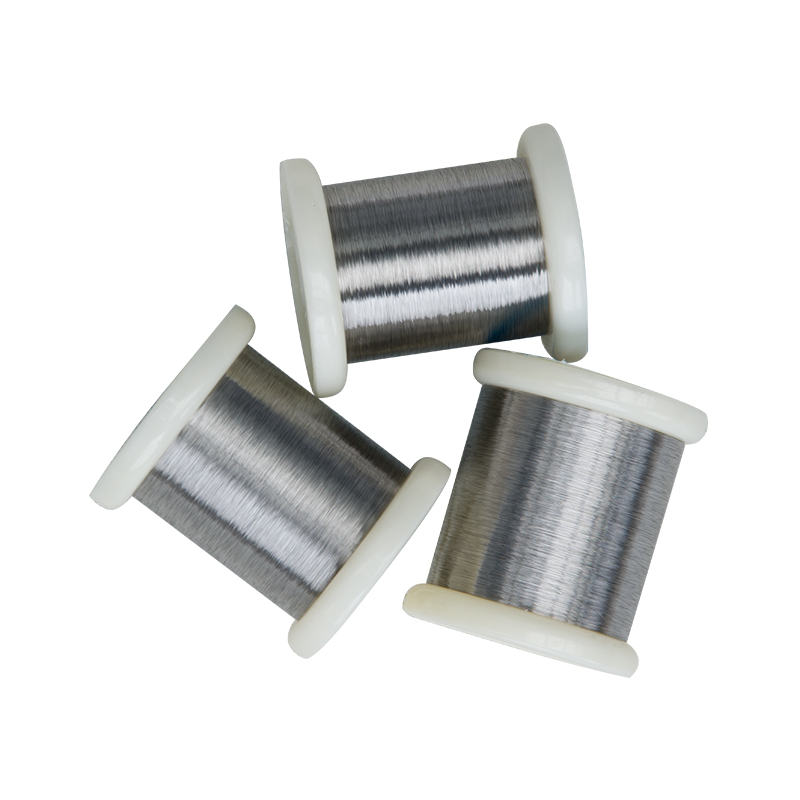

Alyaj Nikèl Hastelloy C276 Ernicrmo-4 Soude MIG TIG Soude Inconel C-276 C22, B3, B2 Fil

Hastelloy se yon alyaj ki reziste korozyon ki baze sou nikèl, ki divize prensipalman an de kategori: alyaj nikèl-kromyòm ak alyaj nikèl-kromyòm-molibdèn. Hastelloy gen bon rezistans korozyon ak estabilite tèmik, epi li sitou itilize nan aviyasyon, domèn chimik, elatriye.

ERNiCrMo-4Yo itilize li pou soude ak gaz-tungstèn-arc ak gaz-metal-arc nan alyaj Inconel C-276 ak lòt alyaj nikèl-chwòm-molibdèn. Akòz gwo kontni molibdèn li, alyaj sa a ofri yon ekselan rezistans kont korozyon anba estrès, krak, korozyon an twou ak nan fant.

Non komen: Oxford Alloy® C-276 FM C-276 Techalloy 276

Estanda: AWS A5.14,ERNiCrMo-4/ ASME II, SFA-5.14, UNS N10276 Werkstoff Nr. 2.4886 ISO SNi6276 Ewòp NiCrMo16Fe6W4

Gwosè: 0.8MM / 1.0MM / 1.2MM / 1.6MM / 2.4MM / 3.2MM / 3.8MM / 4.0MM / 5.0MM

| Klas | C276 | C22 | C4 | N | |||

|

Chimik Konpozisyon (%) | C | ≤0.01 | ≤0.015 | ≤0.015 | ≤0.02 | ≤0.01 | 0.04-0.08 |

| Mn | ≤1 | ≤0.5 | ≤1 | ≤1 | ≤3 | ≤1 | |

| Fe | 4-7 | 2-6 | ≤3 | ≤2 | ≤1.5 | ≤5 | |

| P | ≤0.04 | ≤0.02 | ≤0.04 | ≤0.04 | – | ≤0.015 | |

| S | ≤0.03 | ≤0.02 | ≤0.03 | ≤0.03 | – | ≤0.02 | |

| Si | ≤0.08 | ≤0.08 | ≤0.08 | ≤0.1 | ≤0.1 | ≤1 | |

| Ni | repo | repo | repo | repo | ≥65 | repo | |

| Co | ≤2.5 | ≤2.5 | ≤2 | ≤1 | ≤3 | ≤0.2 | |

| Ti+Cu | – | – | ≤0.7 | – | ≤0.4 | ≤0.35 | |

| Al+Ti | – | – | – | – | ≤0.5 | ≤0.5 | |

| Cr | 14.5-16.5 | 20-22.5 | 14-18 | ≤1 | ≤1.5 | 6-8 | |

| Mo | 15-17 | 12.5-14.5 | 14-17 | 26-30 | ≤28.5 | 15-18 | |

| B | – | – | – | – | – | ≤0.01 | |

| W | 3-4.5 | 2.5-3.5 | – | – | ≤3 | ≤0.5 | |

| V | ≤0.35 | ≤0.35 | – | 0.2-0.4 | – | ≤0.5 | |

Kategori pwodwi yo

-

Telefòn

-

Imèl

-

Whatsapp

-

WeChat

Jidi

150 0000 2421

-

Anlè