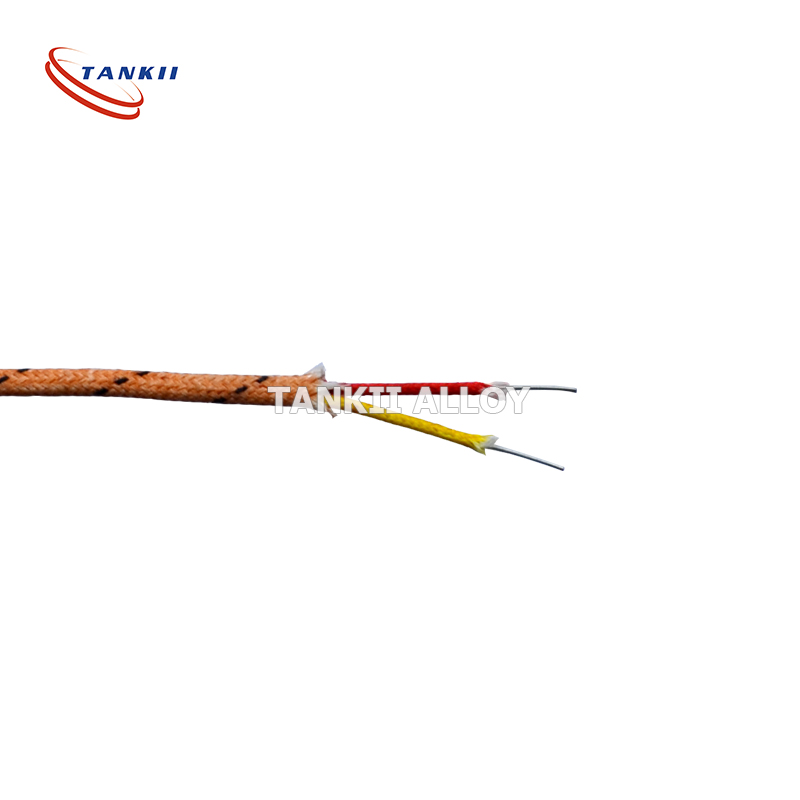

Fil pou espre tèmik alyaj nikèl ak asye pur pi bon kalite Zenk/Monel 400/Tafa 70t/Monel K500/Ernicu-7/Ni95al5/Tafa 75b/Hastalloy C-276

Zenk pi/Monèl 400/Tafa 70t/Monèl K500/Ernicu-7/Ni95al5/Tafa 75b/Hastalloy C-276Fil espre tèmik an asye pur

Deskripsyon pwodwi

1. FM60 Oxford alyaj 60ERNiCu-7Baton soude TIG

ERNiCu-7Li gen bon fòs epi li reziste korozyon nan plizyè medya, tankou dlo lanmè, sèl, ak asid reduktè. Epi li ka itilize pou kouvri asye kabòn, depi yo itilize yon kouch tanpon ERNi-1 pou premye kouch la. Alyaj sa a pa ka dire lontan epi lè yo itilize li pou rantre Monel K-500, li gen mwens fòs pase metal debaz la.

Non komen: Oxford Alloy® 60 FM 60 Techalloy 418

Estanda: AWS 5.14 Klas ERNiCu-7 / ASME SFA 5.14 Klas ERNiCu-7 ASME II, SFA-5.14 UNS N04060 Werkstoff Nr. 2.4377 ISO SNi4060 Ewòp NiCu30Mn3Ti

KONPOZISYON CHIMIK (%)

| C | Si | Mn | S | P | Ni |

| ≤0.15 | ≤1.25 | ≤4.0 | ≤0.015 | ≤0.02 | 62-69 |

| Al | Ti | Fe | Cu | lòt moun | |

| ≤1.25 | 1.5-3.0 | ≤2.5 | Repoze | <0.5 |

PARAMÈT SOUDAJ

| Pwosesis | Dyamèt | Vòltaj | Anperaj | Gaz |

| TIG | .035″ (0.9mm) .045″ (1.2mm) 1/16″ (1.6mm) 3/32″ (2.4mm) 1/8″ (3.2mm) | 12-15 13-16 14-18 15-20 15-20 | 60-90 80-110 90-130 120-175 150-220 | 100% Agon 100% Agon 100% Agon 100% Agon 100% Agon |

| MIG | .035″ (0.9mm) .045″ (1.2mm) 1/16″ (1.6mm) | 26-29 28-32 29-33 | 150-190 180-220 200-250 | 75% Agon + 25% Elyòm 75% Agon + 25% Elyòm 75% Agon + 25% Elyòm |

| SAW | 3/32″ (2.4mm) 1/8″ (3.2mm) 5/32″ (4.0mm) | 28-30 29-32 30-33 | 275-350 350-450 400-550 | Ou ka itilize Flux ki apwopriye Ou ka itilize Flux ki apwopriye Ou ka itilize Flux ki apwopriye |

PWOPRIYETE MEKANIK

| Fòs tansyon | 76,5000 PSI | 530 MPA |

| Fòs sede | 52,500 PSI | 360 MPA |

| Elongasyon | 34% |

APLIKASYON

Yo ka itilize ERNiCu-7 pou aplikasyon soude diferan lè l sèvi avèk divès alyaj nikèl-kwiv pou nikèl 200 ak alyaj kwiv-nikèl.

Yo itilize ERNiCu-7 pou soude ak gaz-tungstèn-arc, gaz-metal-arc, ak ak submerged-arc nan alyaj Monel 400 ak K-500.

ERNiCu-7 la lajman itilize nan aplikasyon maren akòz bon rezistans li genyen kont efè koroziv dlo lanmè ak dlo sale.

2. Lòt fil espre tèmik

| Atik | Kontni chimik | Zn | Cd | Pb | Fe | Cu | Balans Total |

| zenk pi | Valè nominal | ≥99.995 | ≤0.002 | ≤0.003 | ≤0.002 | ≤0.001 | 0.005 |

| Atik | Inconel 625 | Ni95Al5 | 45CT | Monèl 400 | Monèl 500 | HC-276 | Cr20Ni80 |

| C | ≤0.05 | ≤0.02 | 0.01-0.1 | ≤0.04 | ≤0.25 | ≤0.02 | ≤0.08 |

| Mn | ≤0.4 | ≤0.2 | ≤0.2 | 2.5-3.5 | ≤1.5 | ≤1.0 | ≤0.06 |

| Fe | ≤1.0 | Pa disponib | ≤0.5 | ≤1.0 | ≤1.0 | 4.0-7.0 | Pa disponib |

| P | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.02 |

| S | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 |

| Si | ≤0.15 | ≤0.2 | ≤0.2 | ≤0.15 | ≤0.5 | ≤0.08 | 0.75-1.6 |

| Cu | Pa disponib | Pa disponib | Pa disponib | repo | 27-33 | Pa disponib | Pa disponib |

| Ni | repo | repo | repo | 65-67 | repo | repo | repo |

| Co | Pa disponib | Pa disponib | Pa disponib | Pa disponib | Pa disponib | Pa disponib | Pa disponib |

| Al | ≤0.4 | 4-5 | Pa disponib | ≤0.5 | 2.3-3.15 | Pa disponib | Pa disponib |

| Ti | ≤0.4 | 0.4-1 | 0.3-1 | 2.0-3 | 0.35-0.85 | Pa disponib | Pa disponib |

| Cr | 21.5-23 | ≤0.2 | 42-46 | Pa disponib | Pa disponib | 14.5-16 | 20-23 |

| Nb | 3.5-4.15 | Pa disponib | Pa disponib | Pa disponib | Pa disponib | Pa disponib | ≤1.0 |

| Mo | 8.5-10 | Pa disponib | Pa disponib | Pa disponib | Pa disponib | 15-17 | Pa disponib |

| V | Pa disponib | Pa disponib | Pa disponib | Pa disponib | Pa disponib | ≤0.35 | Pa disponib |

| W | Pa disponib | Pa disponib | Pa disponib | Pa disponib | Pa disponib | 3.0-4.5 | Pa disponib |

| Enpurte | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 |

3. C276fil espre tèmik

Non komen: Oxford Alloy® C-276 FM C-276 Techalloy 276

Estanda: AWS A5.14, ERNiCrMo-4/ ASME II, SFA-5.14, UNS N10276 Werkstoff Nr. 2.4886 ISO SNi6276 Ewòp NiCrMo16Fe6W4

KONPOZISYON CHIMIK (%)

| C | Si | Mn | S | P | Ni | Co |

| ≤0.02 | ≤0.08 | ≤1.0 | ≤0.03 | ≤0.04 | Repoze | ≤2.5 |

| W | V | Fe | Cu | Cr | Mo | lòt moun |

| 3.0-4.5 | ≤0.35 | 4.0-7.0 | ≤0.5 | 14.5-16.5 | 15-17 | <0.5 |

Kategori pwodwi yo

-

Telefòn

-

Imèl

-

Whatsapp

-

WeChat

Jidi

150 0000 2421

-

Anlè